Farm-ING Smart Farm Equipment GmbH

Shift-ING 2

Linear displacement

Phone support

Remote maintenance

On-site support

Mail support

Technical data

Our shifting frame with AI-based camera system can be upgraded to any conventional chipper to automate row guidance.

The sliding frame is driven by two electric linear actuators.

The field of application is very diverse and specially designed for the automated row guidance of a conventional hoe in a wide variety of crops in the rear.

When manual steering becomes a challenge, enjoy weed removal again with the support of our ShiftING.

Functionality

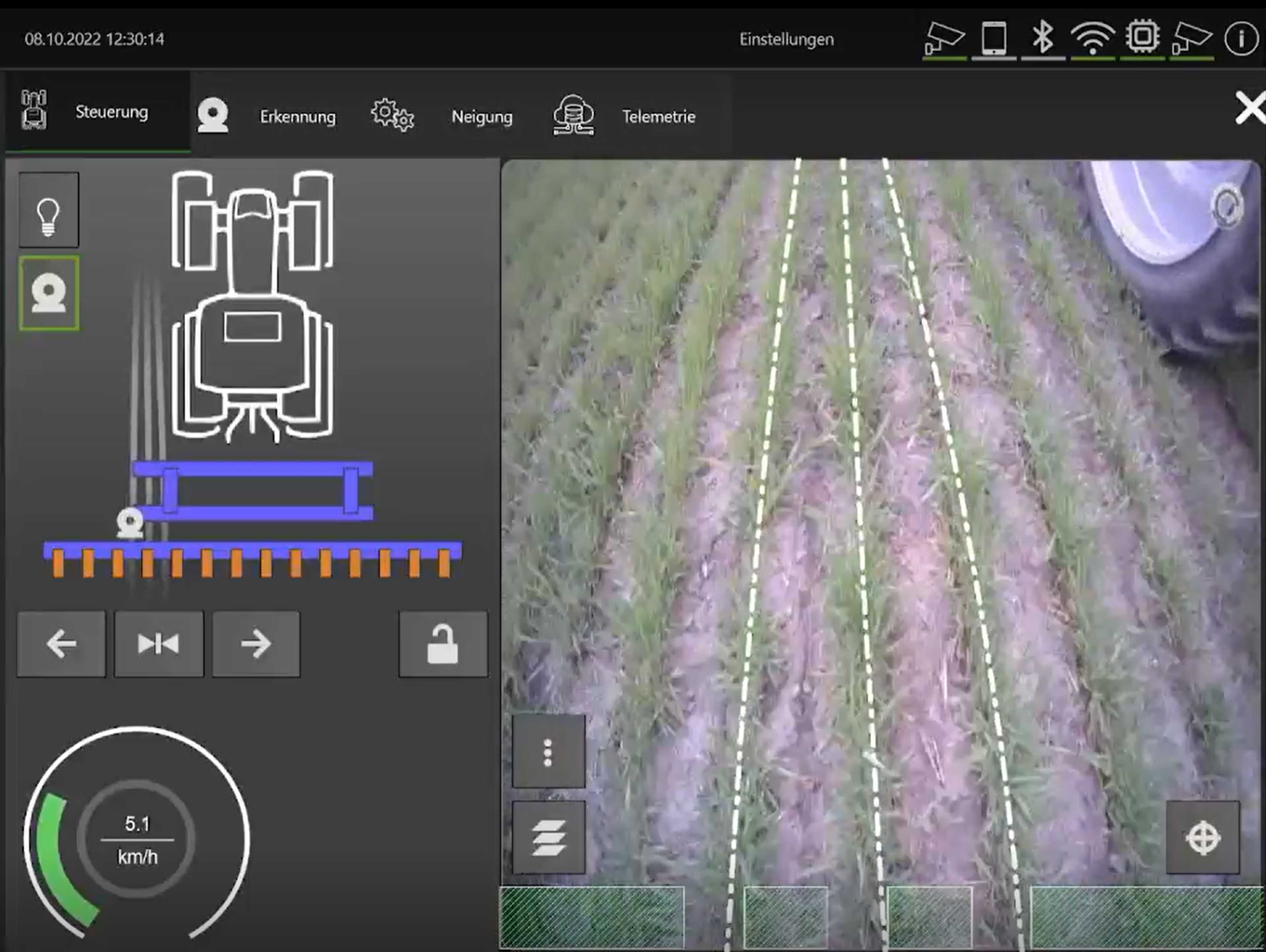

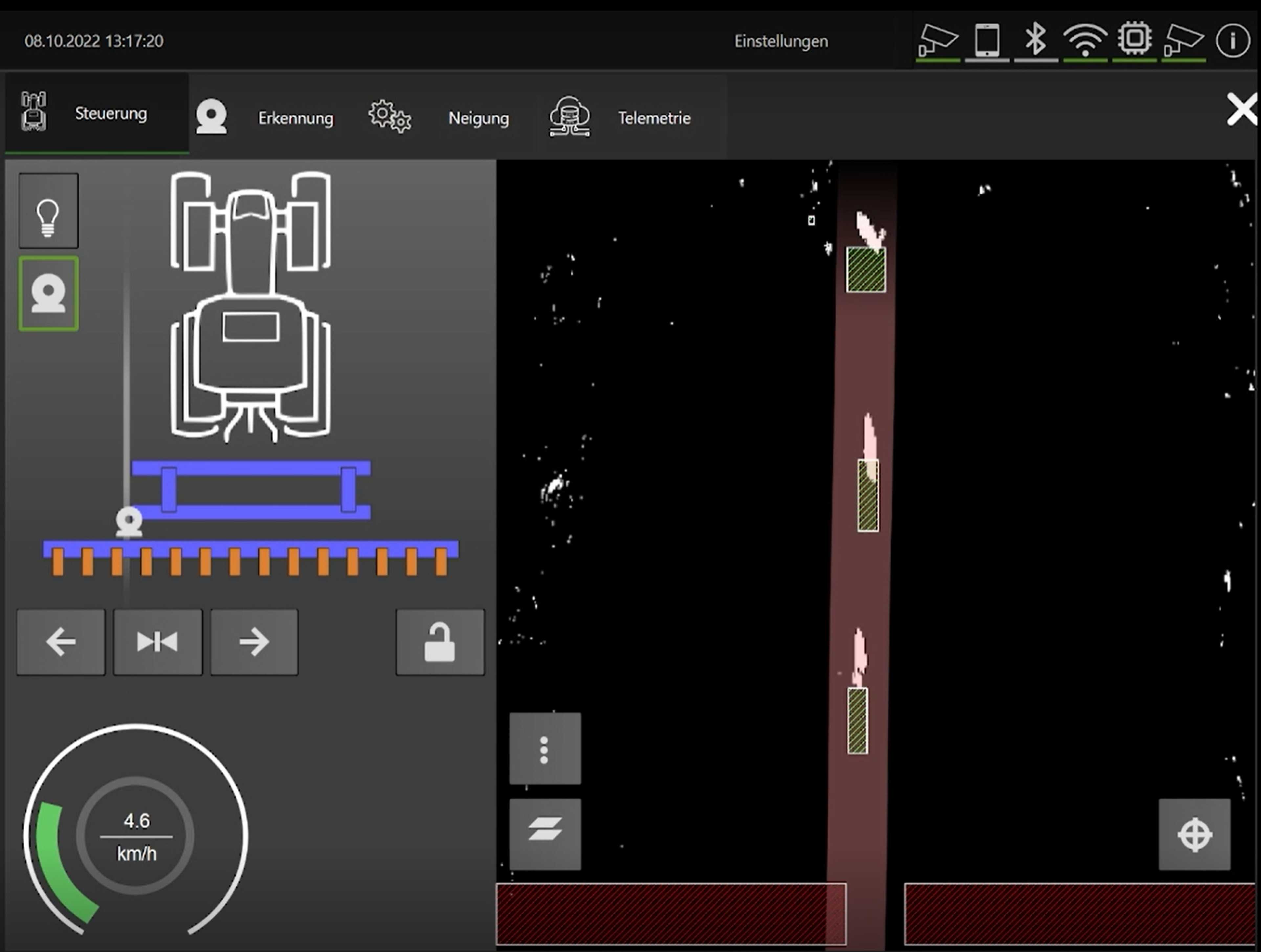

The shovel frame is mounted on the 3-point linkage between the tractor and the implement, and the short design means that the combination remains very compact. The AI-based camera system detects the crop at the smallest growth stages and reliably distinguishes it from weeds. The trailing hoe is aligned to the detected crop rows in fractions of a second using two electric linear actuators to give you maximum working speed. The precise row detection and the backlash-free linear guidance of the shifting frame allow you to keep the hoeing belt narrow. The lateral stability of the ShiftING is guaranteed by the two track guide wheels, which run in the tractor track.

Camera system design

Choose the right camera system design for your operation.

Basic

1 camera detects the plant rows works very well in visible stands

Premium 2 cameras, tilt sensor, AI detection Plant detection based on single plant detection Also suitable for curves, heavily weeded fields and on slopes

Advice is offered on the selection of the appropriate camera system.

Pricing

Attributes

Support

Phone support

Mail support

On-site support

Remote maintenance

Technical data

Recognition technique

Linear displacement

- 1 Camera

- detects the plant rows

- Works very well in visible stocks

- 2 cameras, tilt sensor, AI detection

- Plant detection based on single plant detection

- Also suitable for cornering, heavily weeded fields and on slopes

Accuracy in cm

Crops

Compatibility/method of attachment

Dead weight in kg

Coupling device

Dimensions in m

Power requirement (with hydraulic sideshift)

Track width in m

Passage size in m

Displacement path in mm

Company

Farm-ING Smart Farm Equipment GmbH

Austria

Founding year:

2022